Being able to cut through all kinds of materials, that is what diamond blades are able to do. Diamond saws are the most commonly used tools when it comes to cutting a variety of materials. They are big and strong with a steel core to support the capabilities of the diamond blade. The amount of diamond in the blade is what determines the quality of the cuts it will make.

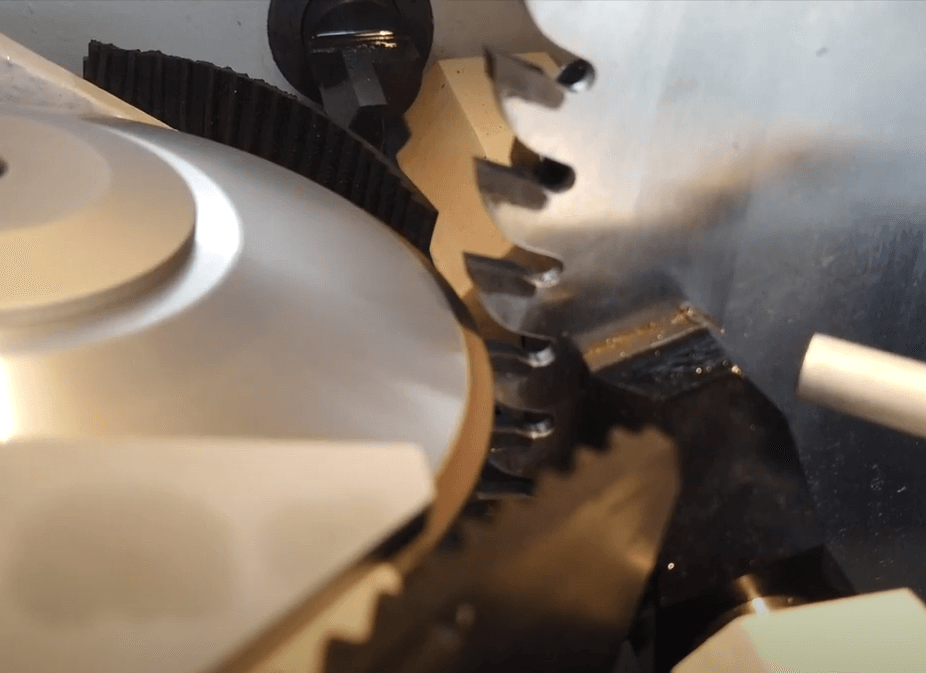

Obviously, the more diamond is present the better the blade will be able to cut through and it will be able to cut through stronger materials too. In fact, because of their structure, diamond blades don’t actually cut, they grind. The exposed diamonds are what helps make the cut possible as the blade rotates. The same diamonds are held by a metal matrix so they don’t go flying when the saw is turning at a high speed.

Types of Diamond Saw Blades

Triple Chip

Like there are saw blades made of different materials there are different types of diamond blades too. A triple chip diamond saw blade is one that has a differentiating tooth pattern. The pattern of triple chip diamond saw blades alternates right-hand and left-hand bevels. This diamond saw blade’s chamfered teeth are able to cut coarsely and then finish off the cut with the flat teeth.

Negative Hook

Negative hook angle saw blades are made to be sued for mitre and radial arm saws too. The tips of the teeth found on this type of saw flank backwards so they slow down the feed tare. This is what helps reduce the risk of kickback making negative hook angle saw blades safer to use.

ATB

Alternate top bevel teeth or ATB saw blades have a bevel design that alternates between left hand and right-hand bevels much like a triple chip blade. The design of ATB blades is suited for a plethora of applications. Thanks to the alternating teeth ATB blades are ideal for making crosscuts and light rip cuts too.

Nail-Resistant

When working with demolition lumber there may be some stuff that can damage the blade. To prevent that from happening you should buy diamond blade that is nail-resistant. This type of saw blade has narrower teeth made of softer carbide which can absorb the shocks from all the gravel or nails.

Anti-Kickback

To prevent a blade from getting carried away you need a design that limits the amount of material that can get cut by each tooth. This design is found on an anti-kickback blade. Oftentimes the teeth of anti-kickback blades are also found on blades with larger gullets a sthey are extremely good at preventing kickback.

HSS

High-speed steel blades are ones that can be sharpened easily. Combined with diamond crystals these blades can be quite powerful especially when it comes to cutting solid wood. Long saws usually use these type of blades.

Carbide-Tipped

If you want something way better than bare blades then go for carbide-tipped blades. These type of saw blades are able to cut up to fifty times longer. You are able to cut plywood, hardwood or even chipboard and still have a sharp blade in the end. Remember, carbide-tipped blades are not that easy to sharpen.

Sintered

Also known as continuous rim blades, sintered blades are long-lasting blades and one that offers excellent performance. This means they are more expensive but also being able to cut at their best for a lot longer. You can find both small and big sintered saw blades as well as premium and economy ones.

Notched

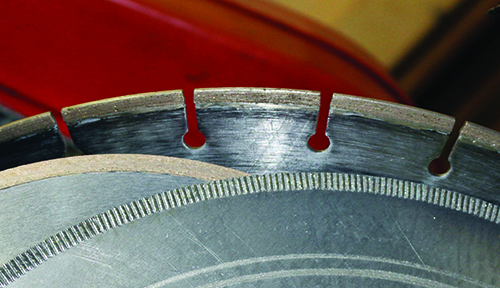

Notched diamond rim blades are made by pressing diamond grit into the edge of a solid steel core. This process leave the blade with small notches alongside the rim. This is the area where the diamond works to cut or rather grind up the material. This is a much more affordable manufacturing process which makes notched blades much more affordable than sintered ones.

This manufacturing process also allows notched diamond saw blades to be very thin making them useful for cutting material with a lot less waste. The notches can be either thin or thick depending on the type of application you’ll use the blade for. Remember that notched blades have less diamond that you can work with making them not as capable as sintered ones.

Electroplated

An electroplated diamond saw blade is one that has a thin layer of diamond electroplated usually with a nickel metal bond onto the surface of its steel core. The diamond is only adhered to the surface of the blade rim it makes for a more capable blade than a notched one. Electroplated saw blades are more affordable than sintered blades but unfortunately, they are not as durable nor as capable. You could think of electroplated saw blades as an option that gives you the best of both worlds. The cutting performance of a sintered blade and the affordability of a notched blade packaged together.